产品单价 |

800.00元/千克 |

起订量 |

100千克 |

供货总量 |

45454 千克 |

发货期限 |

自买家付款之日起3天内发货 |

品牌 |

monelalloy |

包装 |

木箱 |

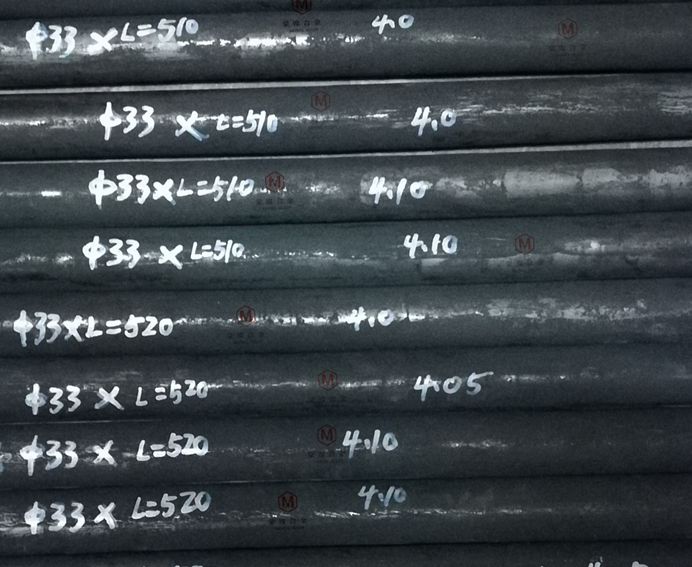

stellite703材质 硬度56HRC 高温磨损腐蚀环境 薄壁零件 耐磨垫片 密封环 各种刀具 拉伸模具陶瓷、 水泥工业、螺旋输送机部件 耐磨损和水溶液腐蚀类钴合金 这类合金成分中都含有5%-13%的Mo,从而耐水溶液腐蚀。牌号有Ultimet,UNS R31233,(5%Mo);stellite21,UNS R30021,(6%Mo); MP159,UNS R30159,(7%Mo);MP35N,UNS R30035,(10%Mo);stellite703(含12%Mo)。 锻压方式对耐磨性能与耐腐蚀性能的益处: 锻压工艺有益于耐腐蚀性能与耐磨性能的机理 锻压改善了化学均质性,这对耐腐蚀具有极为重要的意义。通俗讲,化学均质性,就是“军民团结如一人,试看天下谁能敌”,这种团结(化学均质性)大化了抵抗腐蚀的能力。 锻压工艺,提升了韧性,延伸率>2%(铸造、粉末冶金或GTA方式的耐磨钴合金延伸率<1%),改进了钴基合金内部强化相析出物的几何结构,即显微组织内的块状碳化钨增强了耐磨料磨损性能。细化了晶粒,提升了晶界强度。这种组织结构的韧性,提升了“保家卫国”的能力。 耐热耐磨损钴合金 耐热耐磨损类合金,性能,应用广泛,这类合金的材质硬度HRC40到HRC65,耐热温度600℃到1200℃。 纯耐热耐磨损钴合金:铸造stellite20与stellite1 HRC40-65,延伸率<1%。耐磨粒磨损、滑动磨损、冲蚀磨损。碳化物强化、钴铬钨成分,有stellite12(硬度HRC42);stellite 20(硬度HRC52);stellite 1(硬度HRC62,);常用于模具、刀片、喷嘴、密封环等小零件。铜合金和铝合金的热压模、热挤压模;密封环、耐磨面板、轴承套筒、磨床工件架;螺旋浆叶片;金属切削用刀具等; 耐热耐磨损同时具有高耐蚀性钴合金:铸造stellite703 硬度HRC56,延伸率<1%,碳化物强化、钴铬钼成分,stellite703,超过10%的Mo含量,耐热耐磨的同时耐腐蚀性能更为。 热硬度高的耐热耐磨损钴合金:铸造TRIBALOY T-400 金属间化合物强化、钴铬钼硅成分的合金TRIBALOY T-400,硬度HRC55,延伸率<1%;热硬度更高,用于高温强腐蚀介质中的闸阀、挤塑器等; stellite703材质是钴铬钼系列钴合金;材质硬度高达56HRC;耐腐蚀环境耐磨垫片;真空冶炼,精密铸造方式生产。 高硬度的碳化物使得stellite703具有极其高的耐磨性;高温环境下耐磨垫片,密封环材质。各种刀具,拉伸模;陶瓷、水泥工业螺旋输送机部件;泵的套筒和旋转密封环、磨损面板、轴承套筒以及无心磨床工件架。

1147/5000

Stellite703 Material hardness 56HRC

Wear-resistant gasket sealing ring for thin-walled parts in high temperature abrasion corrosive environment

All kinds of cutting tools, drawing die, ceramic,

Cement industry, screw conveyor components

Cobalt alloy resistant to abrasion and corrosion in aqueous solution

These alloys are all composed of 5%-13% Mo and thus resist corrosion in aqueous solutions. The brand is Ultimet,UNS R31233,(5% MO); stellite21,UNS R30021,(6%Mo); MP159, UNS R30159, Mo (7%); MP35N, UNS R30035, Mo (10%); Stellite703 (containing 12% Mo).

The advantages of forging method on wear resistance and corrosion resistance:

Forging technology is beneficial to corrosion resistance and wear resistance mechanism

Forging improves chemical homogeneity, which is of great importance for corrosion resistance. Commonly speaking, chemical homogeneity is "the army and the people unite as one, who can test the world". This unity (chemical homogeneity) maximizes the ability to resist corrosion.

Forging process improves toughness, elongation > 2% (casting, powder metallurgy or GTA wear resistant cobalt alloy elongation < 1%), improve the geometric structure of cobalt alloy internal strengthening phase precipitates, that is, block tungsten carbide in the microstructure to enhance the wear resistance. The grain size is refined and the grain boundary strength is enhanced. The resilience of this organizational structure has enhanced the ability to "defend the country".

Heat and wear resistant cobalt alloy

Heat and wear resistant alloy, superior performance, widely used, this kind of alloy material hardness HRC40 to HRC65, heat resistance temperature 600℃ to 1200℃.

Pure heat and wear resistant cobalt alloy: cast Stellite20 and Stellite1

HRC40-65, elongation < 1%. Wear abrasive wear, sliding wear, erosion wear. Carbide reinforced, cobalt chromium tungsten composition, Stellite12 (hardness HRC42); Stellite 20 (hardness HRC52); Stellite 1 (hardness HRC62,); It is often used in mold, blade, nozzle, seal ring and other small parts. Hot pressing die and hot extrusion die of copper alloy and aluminum alloy; Sealing ring, wear-resisting panel, bearing sleeve, workpiece frame of grinding machine; Propeller blade; Metal cutting tools, etc.;

Cobalt alloy with high heat and wear resistance and high corrosion resistance: cast stellite703

Hardness HRC56, Eelongation < 1%, carbide reinforced, cobalt chromium molybdenum, Stellite703, more than 10% Mo content, excellent heat and wear resistance and corrosion resistance.

Heat and wear resistant cobalt alloy with high thermal hardness: cast TRIBALOY T-400

Intermetallic compound reinforced alloy Tribaloy T-400, hardness HRC55, elongation < 1%; High thermal hardness, used for high temperature strong corrosive medium gate valve, extruder, etc.;

STELLITE 703 is made of cobalt chromium molybdenum series cobalt alloy; Material hardness up to 56HRC; Corrosion-resistant wear-resistant gasket; Vacuum smelting, precision casting production.

The high hardness of the carbide gives Stellite703 extremely high wear resistance; Wear-resistant gasket and sealing ring material in high temperature environment. All kinds of cutting tools, drawing die; Ceramic, cement industrial screw conveyor parts; Pump sleeve and rotary seal ring, wear panel, bearing sleeve and centerless grinder workpiece

| 上海蒙镍特种合金有限公司 | |||

|---|---|---|---|

| 联系人 | 陈玉兰 |

微信 | 无 |

| 手机 | | 邮箱 | 2959280481@qq.com |

| 传真 | 无 | 地址 | 上海市松江区泗泾镇泗砖路600号 |

| 主营产品 | 高温合金,镍基高温合金,特种不锈钢,铸造高温合金 | 网址 | http://monelalloy.b2b.huangye88.com/ |